MAHESH KUMAR THAPAR

A leader in Coal Mining, with a successful and unparallel exposure spanning 50 years in leading PSUs, Corporates & Government of India.

Seeking challenging assignment in the Advisory / Leadership position in all facets of Coal Mining including Greenfield / Brownfield Mine Development, Regulatory Compliance, Transaction Advisor and Owner/Lender’s engineer.

Profile:

A seasoned leader in Coal Mining, with a successful career spanning 40 years with Coal India Ltd. in various capacities, retiring as Chairman & Managing Director of South Eastern Coalfields Ltd.

Served as Director/Advisor Projects, with Ministry of Coal, Govt. of India.

A proven sector champion who joined corporate sector post retirement. Served as a CEO in Adani Enterprise for 10 years and has reaffirmed his credibility by developing a mining vertical comprising several greenfield coal blocks.

Experience:

Now heading Matrix Mining Solutions Private Limited as Chairman with a view to leverage his experience for A to Z solutions of Mining.

Reports & guidance to their clients given by Matrix Mining Solutions Private Limited (MMSPL)

- Pre-feasibility / Feasibility & Detailed Project Reports were prepared for following coal blocks;

- Khagra-Joydev - 5MTPA

- Pachhwara South -9 MTPA

- Talabira-II &III - 20 MTPA

- Tubed - 6 MTPA

- Guidance in submission of tenders to clients to win contracts of MDO, Washeries ,who have been successful in getting 5-6 contracts.

- Association in formulation of MoU , JVs, Contracts etc.

- Coordinator and project management services on washery tenders floated by CIL subsidiaries.

Highlights

Completed MDO`s tenders of 5-6 projects.In the very first year had a turnover of plus 3 crores. Clients have successfully bid in many coal blocks and have also been awarded contracts .

CEO – Coal Mining Business, Adani Enterprises Limited — Feb.2007 to 30 Oct 2016

- Developed a robust mining vertical in record time encompassing all functions and feudatories

- Won MDO contracts for five coal blocks (of different PSUs) through global tendering.

- Developed a Greenfield project i.e. PEKB within stipulated schedule of MoC & attained its peak capacity of 10 MTPA.

- In perfect harmony with environment, developed a unique technique of two-phase mining, backfilling & Sal transplantation.

- Developed Rail & Road Infrastructure for the mine in a very difficult terrain..

- Dealt with National Green Tribunal (NGT) when Project’s Forest & Environment Clearance was challenged by a NGO.

- Developed a legacy and an organization that is considered “the best” in its field.

- Geological Report, Mining Plan, EC, FC for Parsa East & Kente Basan Coal Block (10/15 MTPA)

- Transaction Advisor including preparation of Detailed Project Report, Pre-feasibility/Feasibility Reports.

- Machhakata Coal Block- 30/50 MTPA

- Chendipada Coal Block- 40 MTPA

- Parsa Coal Block- 5 MTPA

- Budgeting annual/quarterly Plan for all coal blocks

Highlights

Developed a very difficult Greenfield project i.e. PEKB which has 70% forest cover & considered as No-Go area.

Developed within stipulated schedule of MoC, despite it being in No Go Area.

AN ECO-FRIENDLY APPROCH FOR MINING AT PARSA KENTE PROJECT

An Extraordinary Industry Champion In Developing Greenfield Project

- Introduced a unique concept of two phase Mining:

- Phase I - 1st to 15th years (Mining shall be restricted to 40% of forest land).

- Phase II - 16th year till life of the mine (Mining permission over remaining 60% Forest land shall be linked to the reforestation and bio diversity management in phase-I.)

- Sequential mining

- Scientific Void Management - Internal dumping shall start after 3rd year i.e. no external dumping from 4th year onwards with effective top soil mgmt.

- 81% of excavated area shall be reclaimed by the end of mine life

- Simultaneous Afforestation / Plantation (29 new trees to replace 1 tree lost)

- Introduced US make Tree transplantation machine for Transplantation of low girth (less than 60 cm) Sal trees & important species in safety zone & backfilled areas

- Adherence to latest Eco-friendly technology – Surface Miner which eliminates drilling & blasting

- Maximum transportation through belt conveyors within ML area to minimize dust in atmosphere

Introduced Tree Transplanter Machine for Shifting of trees-Ecofriendly Mode

TREE TRANSPLANTATION PROCESS

(LOW GIRTH<60 CM)

(1) SPADES ARMING THE TREE

(2) SCOOPING OUT THE TREE WITH SOIL

ADHERENCE TO LATEST ECO-FRIENDLY TECHNOLOGY – SURFACE MINER WITH SEPARATE STACKING OF COAL AND OVERBURDEN

(MINE OPERATIONS)

IMPLEMENTED SAL TREE TRANSPLANTATION

(EXCEPTIONAL IN COAL MINING INDUSTRY)

PLANTATION-SAL SAPLINGS

REGENERATED-SAL SAPLINGS

DEVELOPED A GREENFIELD PROJECT

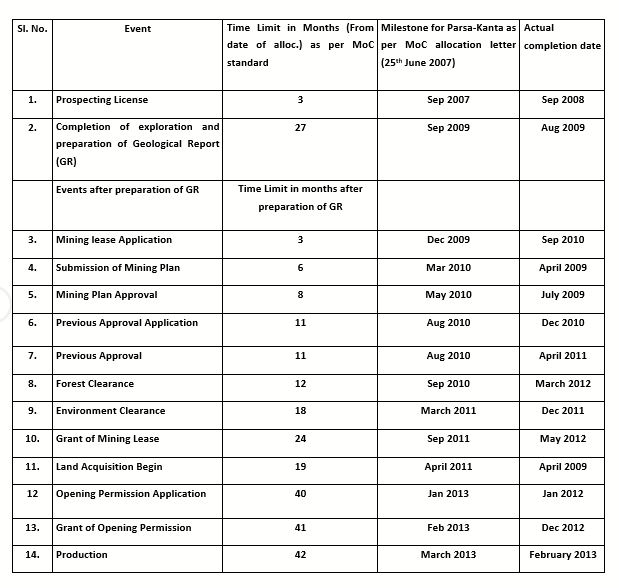

(Milestone Chart of PEKB – MoC Guidelines Vs Actual Date of Completion)

UN-PARALLEL SUCCESS Journey in CIL

CMD - South Eastern Coalfields Limited— May’03 – May’06

- Achieved growth of 17 MTPA coal production in 3 years, which exceeds cumulative growth of the Company during previous decade

- More than doubled the profit in 3 years and implemented forward looking policies resulting in extremely harmonious industrial relations

Highlights

Achieved more growth in 3 years, which has superseded all previous records

CMD and Director (Tech) – Central Coalfields Limited — Oct’01 – May’03

- Implemented successful turnaround of the company from a reported loss of INR 4.6 billion in 2000-01 to a profit of INR 3.9 billion in 2002-03

Highlights

Turned around the company from a perennial loss making unit to profitable in 20 months

Director/Advisor Projects, Ministry of Coal —Apr’99 – Sep’01

- Had exposure to Govt. working and national & international exposure of Coal Industry

Highlights

Looked at National and International Mining Industry

General Manager/Chief General Manager – Jamuna-Kotma, Kusmunda & Gevra /SECL, Rajmahal / ECL — May’94 – Mar’99

- Achieved turn around in Jamuna-Kotma Area, from losses to a profit of INR 80 million, 290 million, and 590 million in the first, three years of placement. The area was awarded overall ‘excellence’ award

- Handled largest coal dispatches to the tune of 24 MTPA during 97-98 in Gevra area

- In Rajmahal introduced various systems on operation & maintenance include financial trimming

- In all assignment introduced system of optimum utilization of all four resources men, machine, material, and money

Highlights

The area was awarded overall ‘excellence’ award

Transformed Gevra as the pride of Coal India where this mine is comparable to any international coal mine in size, efficiency, and cost

Sub-Area Manager / Dy. General Manager - Durgapur / WCL, Manikpur & Gevra / SECL — May’83 – May’94

- Introduced Hot seat change for HEMM operators

- Cut down project construction time

- Introduced healthy system for operation & maintenance resulting in average savings of +5,000 working hours per year from dumpers

- Introduced first Integrated Mine Management System in Coal India

Highlights

Managed the largest capacity in all the assignments in Coal India

Gevra is the largest coal producing unit in India

Education:

B.Sc (Mining Engineering – 1967) - 2nd position in BHU

Mine Manager’s Certificate of Competency (Coal) - 1970 – 1stClass